Die Firmen

Die beiden Firmen erreichen Sie künftig auch direkt:

Die ktc Handhabungstechnik GmbH finden Sie unter www.ktc-handhabungstechnik.de.

Die ktc GmbH finden Sie unter www.ktc-gmbh.com.

ktc Handhabungstechnik GmbH und ktc GmbH

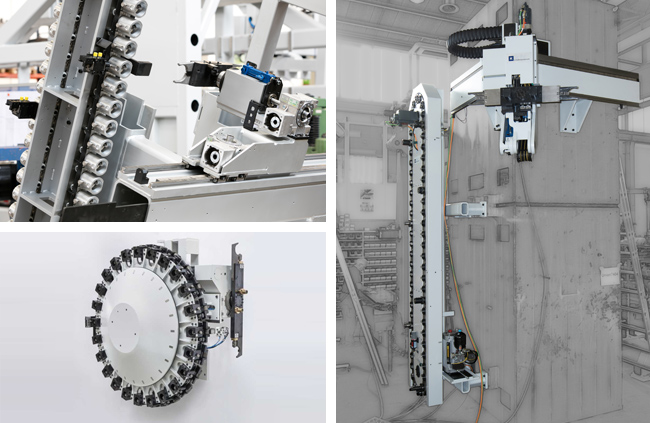

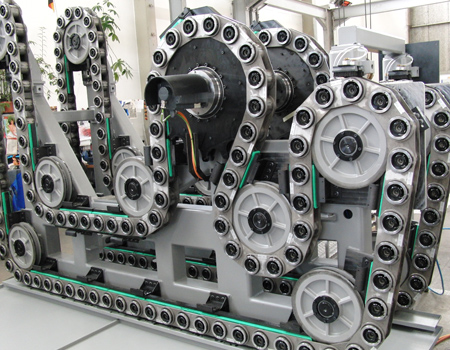

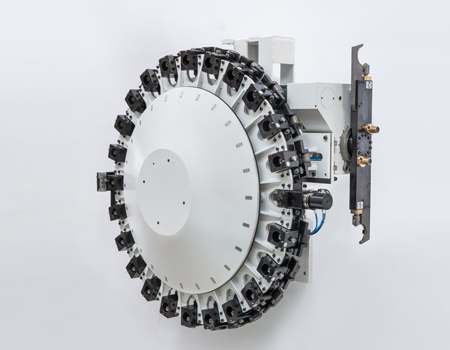

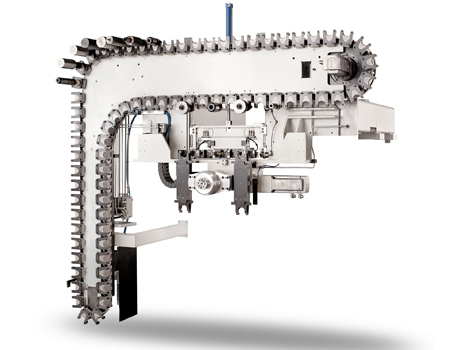

Die ktc Handhandhabungstechnik ist eine moderne Produktionsgesellschaft mit dem Fokus auf der Fertigung von Werkzeugwechsler, Werkzeugwechselsystemen, Dienstleistungen und Montagen im Maschinenbau. Wir fertigen und entwickeln auch für Ihre Werkzeugmaschine das passende System, gleich ob Regalmagazine, Scheibenmagazin, Werkzeugwechsler in Wagenketten oder Werkzeugwechsler in Laschenketten Ausführung. Unsere Dienstleistungen, wie z. B. Konstruktion oder Lohnmontagen, erfüllen stets die hohen Erwartungen unserer Kunden.

Die ktc GmbH befasst sich mit der Fertigung moderner Transformatoren in kleinen und großen Serien, mit Spezialanwendungen und der Fertigung auf Kundenwunsch. Mit der eigenen CNC Fertigung können auch Lohnfertigungen abgewickelt werden. Hier bieten wir neben unserer Entwicklungs- und Konstruktionsdienstleistungen ein komplettes Paket an.

Die Bereiche

Mit über 50 Jahren Erfahrung entwickeln wir Werkzeugwechsler mit hoher Variantenvielfalt. Insgesamt haben wir mehr als 10.000 Werkzeugwechsler und Anlagen an über 200 Maschinen- und Werkzeugmaschinenhersteller ausgeliefert.

Werkzeugwechsler und Systeme

Automatische Werkzeugwechsler tragen maßgeblich zum wirtschaftlichen Maschineneinsatz bei. Bei uns finden Sie für jeden Anwendungsfall die passende Lösung. Ob Regal oder Laschenkette, Scheibenmagazin oder Wagenkette. Die ktc Handhabungstechnik ist immer eine gute Wahl.

Transformatoren

Unser Angebot besteht aus Transformatoren die z.B. zur Spannungswandlung in technischen Geräten und für das Zünden von Oel- und Gasbrennern eingesetzt werden. Dabei fokussieren wir uns nicht nur auf Serienprodukt, sondern auch auf kundenspezifische Lösungen.

Dienstleistungen

ktc GmbH

Als Dienstleister für die Metallverarbeitung, die Montage von Baugruppen und Geräten bieten die ktc Handhabungstechnik GmbH und die ktc GmbH unseren Kunden ein umfassendes Angebot an Leistungen.

ktc Handhabungstechnikktc GmbH